Executive Summary

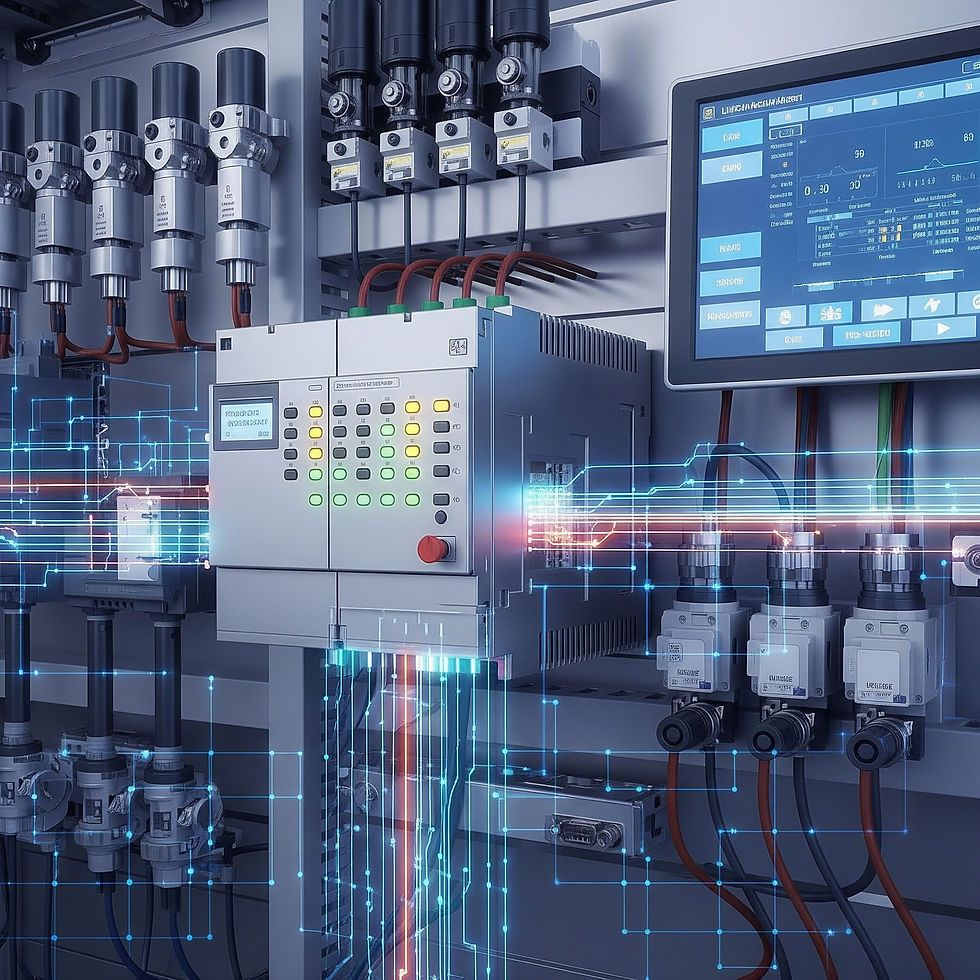

Programmable Logic Controllers (PLCs) remain the foundation of modern industrial automation. Despite the rise of edge computing, IoT, and AI, PLCs are irreplaceable in executing deterministic, real-time control at the machine level. This white paper examines the enduring role of PLC programming, its evolving capabilities, and how it integrates with advanced automation platforms to support scalable, resilient manufacturing systems.

What is PLC Programming?

PLCs are industrial-grade computers that monitor inputs, make logic-based decisions, and control outputs in real time. PLC programming involves writing logic instructions that define how machines behave in response to signals from sensors, switches, or operator interfaces.

Common programming languages include:

Ladder Logic: Visual format mimicking electrical relay schematics

Structured Text: High-level, text-based logic for advanced control and computation

Function Block Diagram (FBD): Modular blocks that simplify control logic

Core Functions of PLCs in Automation

Real-Time Control: Execute logic cycles within milliseconds for high-speed coordination

Safety Interlocks: Prevent dangerous conditions through fail-safe programming

Sequencing: Manage multi-step processes (i.e. pick-place-pack) with conditional logic

Data Logging and Alarms: Record process variables and notify operators of exceptions

Communication: Interface with HMIs, SCADA, MES, and external devices via industrial protocols (i.e. Modbus, Profibus, EtherNet/IP)

Modern Trends in PLC Programming

Integration with Edge and Cloud Systems: Modern PLCs can communicate with edge gateways and cloud platforms, enabling real-time data streaming, visualization, and analytics.

Standardization via IEC 61131-3: The IEC standard allows cross-platform programming compatibility and supports modular code reuse.

Cybersecurity Awareness: New programming practices focus on user authentication, encrypted communication, and secure boot protocols to harden PLCs against network attacks.

Simulation and Virtual Commissioning: Digital twins of PLC logic can be tested in virtual environments to reduce on-site commissioning time and risk.

Strategic Benefits for Manufacturers

High Availability: Designed for rugged environments and continuous uptime

Deterministic Execution: Ensures consistent behavior under all operating conditions

Rapid Diagnostics: Built-in diagnostics and status registers aid maintenance

Future Integration: Compatible with both legacy systems and modern architectures

Real-World Application Example

A packaging manufacturer modernized its PLC infrastructure by consolidating logic across disparate machine types. Results:

25% reduction in downtime through improved sequencing and interlock logic

Faster operator onboarding via unified HMI logic tied to PLC variables

Remote diagnostics enabled through OPC-UA integration

Conclusion

PLC programming continues to underpin industrial automation by delivering stability, control, and performance at the core of every machine operation. As the ecosystem evolves, PLCs will remain essential—now augmented by edge intelligence, AI, and secure networking. Artisan Technologies supports advanced PLC programming and integration to build agile, connected, and future-ready manufacturing environments.

To discuss PLC programming modernization or integration, contact us at sales@artisantec.io or visit www.artisantec.io.

Artisan Technologies | © 2025 All rights reserved